Cathodic Protection Well Standards

Electrolytic Corrosion

For the purpose of these standards, electrolytic corrosion is defined as the deterioration of metallic objects by electrochemical reaction with the environment. The electrolytic corrosion process is illustrated in Figure 4 (Bulletin 74-90) for a metallic pipeline in a soil-water environment. This process gradually weakens the pipeline and can cause its failure.

In Figure 4 (Bulletin 74-90), an electric potential is induced on the surface of the pipeline as a result of variations in the concentrations of salts in the soil and water surrounding the pipeline. This potential results in an electric current in the soil-water electrolyte. Current flows from an "anode area" on the pipeline to a "cathode area" on the pipeline. Metal is removed from the anode area by the current.

Cathodic Protection

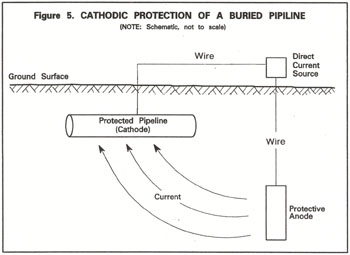

"Cathodic protection" is a term used for certain measures taken to prevent or minimize electrolytic corrosion of metallic equipment and structures. Cathodic protection devices redirect current to flow from a "sacrificial" anode to the soils-water electrolyte, instead of from an anode area on a pipeline or other metallic structure to be protected. The protective anode's role is to corrode in place of the metallic object it is designed to protect, as shown in Figure 5 (B74-90). The protected facility is made to be a permanent cathode by use of cathodic protection devices. Thus, the facility is said to be "cathodically protected."

Protective or sacrificial anodes can be placed close to ground surface or at significant depth. Anodes have been placed at shallow depths in horizontal and vertical arrays for many years. Shallow arrays are often not well suited for metropolitan areas because of land requirements, or suited for areas where electrical interference may be high.

Deep vertical anode installations, usually referred to as "cathodic protection wells," were first developed and used during the 1940s. They were developed in response to the constraints of shallow anode arrays.

Cathodic Protection Wells

Cathodic protection wells are widely installed to protect metallic objects in contact with the ground from electrolytic corrosion. Such objects include petroleum, natural gas, and water pipelines, and related storage facilities; power lines; telephone cables; and switchyards. Cathodic protection wells are sometimes used to control electrolytic corrosion in large water wells.

Many cathodic protection wells have been constructed to protect pipelines that transport natural gas or other "hazardous" materials. The Natural Gas Pipeline Safety Act, Public Law 90-481 adopted by Congress in August 1968, provides requirements for cathodic protection of certain pipelines. Most cathodic protection wells in California are located in areas where underground pipelines or "conveyance" systems are numerous and must be protected. These areas include:

- South coastal region from San Diego to Santa Barbara,

- Oil-producing areas of the southern San Joaquin Valley and the Central Coast, and

- San Francisco Bay Area.

Few cathodic protection wells exist in California north of Sacramento. Many cathodic protection wells, as illustrated in Figure 6 (B74-90), have been constructed by:

-

1. Drilling a 6- to 12-inch diameter borehole to a desired depth. Cathodic protection wells normally range from 100 to 500 feet in total depth. A few wells have been constructed to depths of 800 feet.

California Water Code Section 13711 defines a "cathodic protection well" as an anode installation exceeding 50 feet in depth. Installations less than 50 feet deep are "legally" considered "shallow anodes," not cathodic protection wells. Shallow anode installations are not specifically covered by these standards.

-

2. Placing a string of anodes in the borehole within a designated interval, usually referred to as the "anode interval."

-

3. Backfilling the anode interval around the anodes with an electrically conductive material, such as granular coke.

-

4. Installing a small-diameter vent pipe that extends from the top of the anode interval to land surface, or above. The purpose of the vent pipe is to release generated gases. Medium to large-diameter pipe or casing used in water wells to maintain the well bore and house pumping equipment is not normally used for cathodic protection wells.

-

5. Backfilling the annulus between the vent pipe and borehole wall with an electrically non-conductive fill material to a specific height above the anode interval. Such fill material usually consists of uniform, small- diameter gravel. Its purpose is to provide a permeable medium for migration of gases and to stabilize the walls of the borehole.

In the past this material was sometimes used to fill the annulus between the vent pipe and the borehole wall from the top of the anode interval to land surface. These standards require specific interval(s) of the upper annular space of a cathodic protection well be filled with sealing materials instead of gravel, to protect groundwater quality.

-

6. Sealing the annulus between the vent pipe and the borehole wall, from the top of the non-conductive annular fill to land surface, with sealing material.

-

7. Installing a permanent cover over the well at ground surface.

-

8. Connecting the anode leads to the facility to be protected, possible through an electrical current source.

Individual designs of cathodic protection wells vary.

The protective anodes of a cathodic protection well usually corrode away with time. Thus a cathodic protection well's anodes determine the well's useful life. Anodes are usually designed to last 15 to 20 years.

There has been an increasing tendency to construct cathodic protection wells with large diameter vent pipe or casing so that anodes can be replaced through the casing. Anode replacement through casing eliminates the need to drill replacement wells when anodes have been expended.

Corrosion Coordinating Committees

Serious electrical interference problems can occur where cathodic protection networks crisscross one another or are too close to one another. Also, stray currents produced from electrical transmission lines and other equipment can sometimes interfere with the operation of cathodic protection systems. Interference problems are usually most pronounced in urban areas.

Corrosion control coordinating organizations have been formed in areas of California to overcome system interferences and other problems. Most organizations are affiliated with or are chapters of the National Association of Corrosion Engineers.

Corrosion control organizations represent the majority of utilities and other groups that install cathodic protection devices, including cathodic protection wells. Organization members coordinate the installation and operation of cathodic protection facilities with the goal of minimizing problems of electrical interference.

Four organizations that deal with Central and Southern California are:

-

Southern California

The Southern California Cathodic Protection Committee is a formal committee covering all of Southern California south of San Luis Obispo, Kern, and Inyo counties, except San Diego County.

-

San Diego County

The San Diego County Underground Corrosion Control Committee is an informal organization that deals with the San Diego area.

-

Central California

The Central California Cathodic Protection Committee is a formal committee covering all of Central California plus Sacramento Valley counties, and western Sierra Nevada mountain counties south of Plumas County.

-

San Francisco Bay Area

The activities of the two committees that formerly covered the San Francisco Bay Area have been assumed by the San Francisco Section of the National Association of Corrosion Engineers. The committees were disbanded in 1985.

No coordinating organizations function in coastal counties north of San Francisco or in the northeastern part of the State.

Unfortunately, not all who install and operate cathodic protection facilities work with a corrosion coordinating organization. Those not associated with an organization are usually individuals or local agencies that are sometimes unaware of the existence of other installations. Non-coordinated facilities can seriously interfere with one another electrically.

Need for Cathodic Protection Well Standards

Cathodic protection wells, along with other types of wells, can allow groundwater quality degradation to occur. Improperly constructed or destroyed cathodic protection wells can constitute a preferential pathway for the movement of poor-quality water, pollutants, and contaminants. Cathodic protection wells constructed with gravel backfill to land surface are particularly conducive to the movement of poor-quality water, pollutants, or contaminants.

Water and electrolytes are sometimes introduced into cathodic protection wells through vent pipes, or gravel fill in the annulus, to keep wells functional where natural electrolytes are lacking. Such a practice could be considered "waste disposal" and may be illegal if poor-quality water is used.

Permanently inactive cathodic protection wells pose a threat for the movement of poor-quality water, pollutants, and contaminants, and should be properly destroyed. Permanently inactive cathodic protection wells are a threat to groundwater quality because they become dilapidated with time, are sometimes forgotten, and are sometimes used for waste disposal.

Many cathodic protection wells have small diameter vent pipes that prevent entry by persons and most animals. However, large vent pipe sizes can pose a serious safety threat if left open at land surface.

History of Cathodic Protection Well Standards

The California Legislature enacted legislation in 1949 directing the California Department of Water Resources to develop recommended water-quality protection standards for the construction and destruction of wells. The Legislature amended the Water Code in 1968 to require standards for cathodic protection wells.

Cathodic protection well standards for California were first published in 1973 as DWR Bulletin 74-1, Cathodic Protection Well Standards: State of California. Standards presented here replace those contained in Bulletin 74-1. Additional discussion on the history of well standards is contained in the Introduction of Bulletin 74-81 and the Introduction of Bulletin 74-81.

Scope of Standards

The following are recommended minimum standards for construction, alteration, maintenance, and destruction of cathodic protection wells in California. They only serve as minimum guidelines toward ensuring cathodic protection wells do not constitute a significant pathway for movement of poor-quality water, pollutants, and contaminants. These standards do not ensure a cathodic protection well will perform its corrosion protection function adequately.

The functional requirements for cathodic protection wells may conflict with the application of certain standards for the protection of water quality. Consequently, some compromise has been made between well function and resource protection in the development of these standards.

Organization of Standards

These standards are arranged in a format similar to the Water Well Standards. Since many of the standards that apply to water wells also apply to cathodic protection wells, many references are made in these standards to the Water Well Standards. Standards that apply only to cathodic protection wells or that require emphasis for cathodic protection wells, are discussed in detail in these standards.Quick Links

- Bulletin 74-81 Introduction

- Bulletin 74-90 Introduction

- Part I. General, Water Well Standards

- Part II. Water Well Construction

- Part III. Destruction of Water Wells

- Monitoring Well Standards, Introduction

- Part I. Monitoring Well Standards, General

- Part II. Monitoring Well Construction

- Part III. Destruction of Monitoring Wells

- Cathodic Protection Well Standards

- Part I. General, Cathodic Protection Well Standards

- Part II. Cathodic Protection Well Construction

- Part III. Destruction of Cathodic Protection Wells

- Appendices