Appendices

APPENDIX A - DEFINITION OF TERMS

The following terms are defines as used in this report:

Abandoned Well - A well whose use has been permanently discontinued or which is in such a state of disrepair that no water can be produced. Because abandonment is a state that also involves intent on the part of the well owner, a definition that prescribes a set of conditions and a time limit for use in applying standards appears in Section 21 of this report.

Active Well - An operating water well.

Annular Space - The space between two well casings or between the casing and the wall of the drilled hole.

Aquifer - A geologic formation, group of formations or part of a formation that is water bearing and which transmits water in sufficient quantity to supply springs and pumping wells.

Artesian Well - A well which obtains its water from a confined aquifer. The water level in an artesian well stands some distance above the top of the aquifer it taps. Where the pressure is sufficient to force the water level above the surface of the ground, the well is termed a flowing artesian well.

Bailer - A long narrow bucket with a valve in the bottom used to remove cuttings or fluids from a well.

Bentonite - A highly plastic colloidal clay composed largely of montmorillonite used as a drilling fluid additive or as a sealant.

Casing - A tubular retaining structure which is installed in the well bore to maintain the well opening.

Cathodic Protection - A technique to prevent the corrosion of a metal surface by making that surface the cathode of an electrochemical cell. (Source: National Association of Corrosion Engineers Standard RP-01-69 or RP-05-72.)

Cement, Portland Cement - A cement that contains oxides of calcium, aluminum, iron, and silicon made by heating a mixture of limestone and clay in a kiln and pulverizing the resultant clinker, as defined in ASTM C150. Portland cement is also considered a hydraulic cement, because it must be mixed with water to form a cement-water paste with the ability to develop strength and harden, even under water.

Centralizer - A device that assists in centering tubular materials in a borehole.

Clay - A fine-grained geologic material (grain size less than 0.004 mm in diameter) which has very low permeability.

Conductor Casing - A tubular retaining structure installed in the upper portion of a well between the wall of the drilled hole and the inner well casing.

Conductance, Specific - A measure of the ability of water to conduct electric current at 77 degrees Fahrenheit. It is related to the total concentration of irons in the water.

Cone of Depression - A depression in the water table or piezometric surface of a groundwater body that is in the shape of an inverted cone and develops around a well which is being pumped. It defines the area of influence of the pumping well.

Confined Groundwater - Groundwater under pressure whose upper surface is the bottom of an impermeable bed or a bed of distinctly lower permeability than the material in which the confined water occurs. Confined groundwater moves under the control of the difference in head between the intake and discharge areas of the water body.

Connate Water - Water entrapped in the interstices of a sedimentary rock at the time it was deposited. These waters may be fresh, brackish, or saline in character. Usually applies only to water found in geologically older formations.

Consolidated Material - A geological material whose particles are stratified, cemented, or firmly packed together; usually occurs at depth, e.g. sandstone.

Contamination - Defined in Section 13050 of the California Water Code:

“(k) “Contamination” means an impairment of the quality of the waters of the state by waste to a degree which creates a hazard to the public health through poisoning or through the spread of disease. “Contamination” shall include any equivalent effect resulting from the disposal of waste, whether or not waters of the state are affected.”

Corrosion - The deterioration of a material, usually a metal, because of a reaction with its environment. (Source: National Association of Corrosion Engineers Standard RP-01-69 or RP-05-72.)

Destroyed Well - A well that has been properly filled so that it cannot produce water nor act as a vertical conduit for the movement of groundwater.

Deterioration - An impairment of water quality.

Drilled Well - A well for which the hole is excavated by mechanical means such as the rotary or cable tool methods.

Driller’s Mud - A fluid composed of water and clay used in the drilling (primarily rotary) operation. The mud serves to remove cuttings from the hole, to clean and cool the bit, to reduce friction between the drill stem and the sides of the hole, and to plaster the sides of the hole. Such fluids range from relatively clear water to carefully prepared mixtures of special purpose compounds.

Drilling Fluid - A fluid (liquid or gas) used in drilling operations to remove cuttings from a borehole, to clean and cool the drilling bit, to reduce friction between the drill stem and the borehole wall, and, in some cases, to prevent caving or sloughing of the borehole.

Drive Shoe - A forged steel collar with a cutting edge fastened onto the bottom of the casing to shear off irregularities in the hole as the casing advances, and to protect the lower edge of the casing as it is driven.

Gravel Packed Well - A well in which filter material (sand, gravel, etc.) is placed in the annular space between the casing and the borehole to increase the effective diameter of the well, and to prevent fine-grained material from entering the well during pumping.

Electrolyte - A chemical substance or mixture, usually liquid, containing ions that migrate in an electric field. The term electrolyte refers to the soil or liquid adjacent to, and in contact with a buried or submerged metallic structure including the moisture and other chemicals contained therein. (Source: National Association of Corrosion Engineers Standard RP-01-69 or RP-05-72.)

Groundwater - That part of the subsurface water which is in the zone of saturation.

Groundwater Basin - A groundwater basin consists of an area underlain by permeable materials which are capable of storing or furnishing a significant water supply; the basin includes both the surface area and the permeable materials beneath it.

Grout - A fluid mixture of cement and water of a consistency that can be forced through a pipe and placed as required. Various additives, such as sand, bentonite, and hydrated lime, are used to meet certain requirements. For example, sand is added when considerable volume of grout is needed.

Impairment - A change in quality of water which makes it less suitable for beneficial use.

Impermeable - That property of a geologic material that renders it incapable of allowing water to move through it perceptibly under the pressure differences ordinarily found in subsurface water.

Impervious Strata - A geologic unit which will not transmit water in sufficient quantity to furnish an appreciable supply to wells or springs.

Inactive Well - A well not routinely operated but capable of being made an operating well with a minimum of effort.

Interference - The situation that arises when a foreign substructure is affected in any way by a direct current source. (Source: National Association of Corrosion Engineers Standard RP-01-69 or RP-05-72.)

Packer - A device used to plug or seal a well at a specific point; frequently used as retainers to keep grout in position until it “sets”.

Perforations - Openings in a well casing to allow the entrance of groundwater into the well. Perforations may be made either before or after installations of the casing.

Permeability - The capacity of a geologic material for transmitting a fluid. The degree of permeability depends upon the size and shape of the openings and the extent of the interconnections.

Pollution - Defined in Section 13050 of the California Water Code:

“(1) “Pollution” means an alteration of the quality of the waters of the state by waste to a degree which unreasonably affects: (1) such waters for beneficial uses, or (2) facilities which serve such beneficial uses. “Pollution” may include “contamination”.”

Protective Anode - A metallic object designed to corrode in place of the object it is designed to protect.

Quality of Water or Water Quality - Defined in Section 13050 of the California Water Code:

“(g) “Quality of the water” or “quality of the waters” refers to chemical, physical, biological, bacteriological, radiological, and other properties and characteristics of water which affect its use.”

Rectifier - An electronic device that changes alternating current to direct current. (Source: National Association of Corrosion Engineers Standard RP-01-69 or RP-05-72.)

Screen or Well Screen - A factory-perforated casing used in a well that maximizes the entry of water from the producing zone and minimizes the entrance of sand.

Tremie - A tubular device or pipe used to place grout in the annular space. Originally designed for placing concrete under water, the discharge end of the tube is kept submerged in the freshly deposited grout so as not to break the seal while filling the annular space.

Unconfined (free) Groundwater - Groundwater that has a free water table, i.e., water not confined under pressure beneath relatively impermeable rocks.

Unconsolidated Material - A sediment that is loosely arranged or unstratified, or whose particles are not cemented together occurring either at the surface or at depth.

Waste - Defined in Section 13050 of the California Water Code:

“(d) “Waste” includes sewage and any/all other waste substances, liquid, solid, gaseous, or radioactive, associated with human habitation, or of human or animal origin, or from any producing, manufacturing, or processing operation of whatever nature, including such waste placed within containers of whatever nature prior to, and for purposes of, disposal.”

Appendix B - SUGGESTED METHODS FOR SEALING THE ANNULAR SPACE AND FOR SEALING-OFF STRATA

Sealing the Annular Space

The annular space is the space between the well casing and wall of the drilled hole created during construction. This space must be adequately sealed to prevent the entrance of surface drainage or poor quality subsurface water, which may contaminate or pollute the well. This seal will also protect the casing against corrosion and possible structural failure.

A number of acceptable sealing methods are presented in this appendix. Other methods may be suggested by individual well drillers on the basis of their experience and availability of equipment. An acceptable method should provide for the complete filling of the sealing interval with the appropriate sealing material to the specified depth.

General

Prior to sealing, the annular space should be flushed to remove any loose formation material or drilling mud that might obstruct the operation. The use of centralizers – devices which are affixed to the casing at regular intervals to prevent it from touching the wall of the hole, thereby keeping the casing centered in the borehole – are recommended. This assures that the seal is not less than the desired minimum thickness. It is particularly significant for large diameter wells where the casing exceeds 10 inches in diameter.

The use of the tremie or grout pipe for the introduction of the sealing material into the annular space is preferred. Where a tremie or grout pipe is used, the minimum annular space should be 2 inches and the minimum tremie size should be a nominal 1-1/2 inches in diameter.

Gravity installation without a grout pipe or tremie should not be attempted when the sealing interval contains water or cannot be visually inspected (with the aid of a mirror or light). Where sealing material is to be introduced under water or the interval cannot be observed from the surface, methods involving “positive” placement (by a tremie or grout pipe, pumping or other application of pressure) must be used.

The sealing material must always be introduced at the bottom of the interval to be sealed. This prevents “bridging” (jamming) or segregation (separation of large aggregate from the mixture in sand-cement or concrete grouts) of the sealing material and eliminates gaps.

Sealing should be accomplished in one continuous operation. Where the sealing interval will exceed 100 feet in length, consideration must be given to the collapse strength of the casing. Further, because of the weight of such extensive seals, consideration must also be given to the installation of stronger retaining devices and to staging the placement of the seal (as, for example, the installation of a short segment of rapid- setting sealant in advance of the main body of sealing material; the former becomes a foundation to support the extensive seal).

Sealing Methods

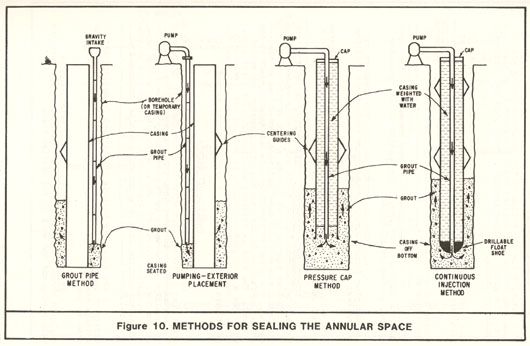

The following methods can be used to seal the upper portion of the annular space. Except for the first, these methods are illustrated on Figure 10. The first method is frequently used where short seals, under 20 feet deep, are placed in dry material.

Gravity Installation (Without Tremie). In this method sealing material is poured into the annular space without the use of a tremie or grout pipe. It cannot be used where the annular space contains water and is limited to intervals less than 30 feet deep. When used, visual observation (with the aid of a mirror or light) should be made during placement of the seal.

Grout Pipe Method. In this method, the seal is placed in the annular space by gravity through a grout pipe (or tremie) suspended in the annular space (see Figure 10).

- 1. Drill the hole large enough to accommodate the grout pipe (at least 4 inches, greater in diameter than the diameter of the casing).

- 2. In caving formations, install a conductor casing.

- 3. Provide a packer or grout retainer in the annular space below the interval to be sealed.

- 4. Extend the grout pipe down the annular space between the casing and the wall or conductor to near the bottom of the interval to be sealed just above the retainer.

- 5. Add grout in one continuous operation, beginning at the bottom of the interval to be sealed. The bottom end of the grout pipe should remain submerged in the sealing material during the entire time it is being placed. The grout pipe is gradually withdrawn as the sealing material is placed. Where a conductor casing is used to hold back caving material, it may be withdrawn as the sealing material is placed.

Pumping-Exterior Placement. For this method the same procedure as described for the Grout Pipe Method (above) is followed except that the material is placed by pumping instead of by gravity flow. The grout pipe must always be full of sealing material and its bottom end must remain submerged in the sealing material until the interval has been filled.

Pressure Cap Method. In the pressure cap method, the grouting is done with the hole drilled about 2 feet below the bottom of the conductor casing and the remainder of the well drilled after the grout is in place and set. The grout is placed through a grout pipe set inside the conductor casing.

- 1. The casing is suspended about 2 feet above the bottom of the drilled hole and filled with water.

- 2. A pressure cap is placed over the conductor casing and grout pipe extended through the cap and casing to the bottom of the hole.

- 3. The grout is forced through the pipe, up into the annular space around the outside of the conductor casing, to the ground surface.

- 4. When the grout has set, the pressure cap and the plug formed during grouting are removed and drilling of the rest of the well is continued.

Because there is the possibility that coarse aggregate will “jam” the grout pipe, concrete cannot be used as a sealant when this method is used.

Continuous Injection. This method, called the Normal Displacement Method in the oil industry (which developed it), involves pumping grout through a tube or pipe centered in the casing via a “float shoe” fitted at the bottom of the casing. The gout is forced up into the annular space to the ground surface as is the case with the pressure cap method (above). The tube is detached and flushed. The float shoe, which has a back pressure valve, is drilled out. Because there is the possibility that coarse aggregate will “jam” the grout pipe, concrete cannot be used with this method.

Sealing-off Strata

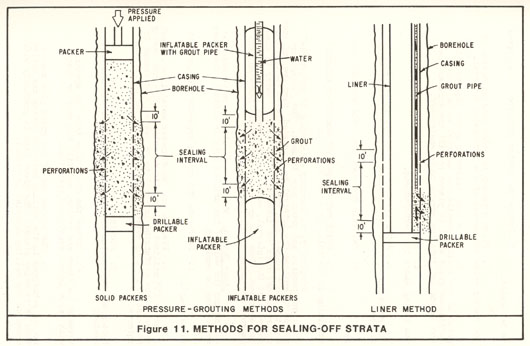

When the hole for a well is drilled, a strata may be found that produces water of undesirable quality. To prevent the movement of this water into other strata and to maintain the quality of the water to be produced by the well, such strata must be sealed-off. Also, where a highly porous non-water producing strata is encountered, it too must be sealed-off to prevent the loss of water or hydraulic pressure from the well.

The following methods can be used in sealing-off strata or zones (see Figure 11). In addition, several of the methods described for sealing the upper annular space can also be used.

Pressure-Grouting Method. This method can be employed where a substantial annular space exists between the well casing and the wall of the drilled hole.

- 1. Perforate the casing opposite the interval to be sealed.

- 2. Place a packer or other sealing device in the casing below the bottom of the perforated interval.

- 3. Use a dump bailer or grout pipe to place grout in the casing opposite the interval to be sealed. Sufficient grout shall be placed to fill the annular space and extend out into the strata to be sealed-off.

- 4. Place a packer or other sealing device in the casing above the perforations.

- 5. Apply pressure to the top packer to force the grout through the perforations into the interval to be sealed.

- 6. Maintain pressure until the material has set.

- 7. Drill out the packers and other material remaining in the well.

Frequently, an assembly consisting of inflatable (balloon) packers and grout pipe is used. The packers are placed to enclose the interval to be sealed, they are inflated and the grout pumped down the hose (which passes through the upper packer) into the interval to be sealed. Water is then pumped into the interval, squeezing the grout through the perforations. When the grout is sufficiently hardened, the packers are deflated and removed.

Liner Method. Where the annular space between the casing and the wall of the drilled hole is minimal, the liner method can be employed.

- 1. Perforate the casing opposite the interval to be sealed.

- 2. Place a smaller diameter metal liner, about 2 inches less in diameter, inside the casing opposite the perforated interval to be sealed, and extend it at least 10 feet above and below the perforated interval.

- 3. Provide a grout retaining seal at the bottom of the annular space between the liner and the well casing.

- 4. Extend the grout pipe into the opening between the liner and casing, and fill the annular space with grout in one continuous operation.

- 5. The bottom end of the grout pipe should remain submerged in the sealing material during the entire time it is being placed. The grout pipe is gradually withdrawn as the sealing material is placed.

APPENDIX C (Bulletin 74-90) - REFERENCES

Since Bulletin 74-81 was published in mid-1981 several new or revised publications have been issued that address groundwater or well construction. This appendix lists publications issued or revised since 1981 and selected other publications that were reviewed during the preparation of this supplement. Publications that were used for Bulletin 74-81 that have since been revised are identified by a number in parentheses. These numbers refer to the publication’s original position in the bibliography of Bulletin 74-81 (Appendix E).

Books and Pamphlets

Aller, Linda. Methods for Determining the Location of Abandoned Wells. A cooperative study by the National Water Well Association, East Central University, and the Robert S. Kerr Environmental Research Laboratory, U. S. Environmental Protection Agency. National Water Well Association. January 1984.

American Society of Agricultural Engineers. Designing and Constructing Irrigation Wells. ASAE Engineering Practice: ASAE EP 400.1. Revised February 1987.

American Society for Testing and Materials. Proposed Recommended Practice for Design and Installation of Groundwater Monitoring Wells in Aquifers. Unnumbered, undated draft.

American Water Works Association. Standard for Backflow Prevention Devices - Reduced Pressure Principle and Double Check Valves. AWWA C506-78 (R83). 1983.

Design and Construction of Small Water Systems; A Guide for Managers. 1984.

Standard Specifications for Deep Wells. AWWA A100-84. 1984 (6).

Steel Water Pipe -- A Guide for Design and Installation. AWWA Manual No. M11. 1985.

Centrifugal Pump Fundamentals. Pumps and Motor Series - Part 1. 1987.

Review of Water Industry Plastic Pipe Practices. Research Report. Prepared by Department of Civil Engineering, University of California, Berkeley. 1987.

Standard for Disinfection of Wells. AWWA C654-87. 1987.

Byron Jackson, Inc. Applied Engineered Cementing. Volume I. Undated.

California Department of Food and Agriculture. Sampling for Pesticide Residues in California Well Water: 1986 Well Inventory Data Base. First Annual Report to the Legislature, State Department of Health Services and State Water Resources Control Board pursuant to the Pesticide Contamination Prevention Act. December 1, 1986.

California Department of Health Services. Organic Chemical Contamination of Large Public Water Systems in California. April 1986.

California Governor’s Task Force on Toxics, Waste and Technology. Final Report. Two volumes. May 1986.

California State Public Utilities Commission. General Order No. 112-C; Rules Governing Design, Construction, Testing, Maintenance and Operation of Utility Gas Gathering, Transmission and Distribution Piping Systems. Effective April 30, 1971. Revised January 18, 1977.

California State Water Resources Control Board. Leaking Underground Fuel Tank (LUFT) Field Manual: Guidelines for Site Assessment, Cleanup, and Underground Storage Tank Closure. State of California. December 1987.

California Water Resources Center, University of California, Davis. Proceedings of the Fifteenth Biennial Conference on Groundwater. September 23-25, 1985. In cooperation with the California Department of Water Resources and the California State Water Resources Control Board. April 1986.

Proceedings of the Sixteenth Biennial Conference of Groundwater. September 22-23, 1987. In cooperation with the California Department of Water Resources and the California State Water Resources Control Board. May 1988.

Congress of the United States, Office of Technology Assessment. Protecting the Nation’s Groundwater from Contamination. Two volumes. October 1984.

Halliburton Company. Halliburton Cementing Tables. 1981.

Illinois Department of Energy and Natural Resources, Illinois State Water Survey and Illinois State Geological Survey. Procedures for the Collection of Representative Water Quality Data from Monitoring Wells. 1981.

Illinois State Water Survey. A Guide to the Selection of Materials for Monitoring Well Construction and Groundwater Sampling. ISWS Contract Report 327. 1983.

Johnson Division, Signal Environmental Systems, Inc. Fletcher P. Driscoll, Principal Author and Editor. Groundwater and Wells. 1986. (44)

Le Grand, Harry E. A Standardized System for Evaluating Waste-Disposal Sites. Second Edition. National Water Well Asociation. 1983.

Morrison, Robert D. Groundwater Monitoring Technology - Procedures, Equipment and Applications. Timco Manufacturing Company, Inc. 1983.

The Engineers’ Manual for Water Well Design. 1985.

National Association of Corrosion Engineers. Recommended Practice -- Control of External Corrosion on Underground or Submerged Metallic Piping Systems. NACE Standard RP-01-69. 1983 Revision.

Recommended Practice -- Design, Installation, Operation, and Maintenance of Impressed Current Deep Groundbeds. NACE Standard RP-05-72. June 1972.

Western Region. Proceedings -- Western States Corrosion Seminar -- V, California State Polytechnic College, Pomona, California, May 4-6, 1971. 1972.

National Sanitation Foundation. Standard 14-Plastic Piping System Components and Related Materials. Revised December 1988.

ANSI/NSF 60 - 1988. Drinking Water Treatment Chemicals - Health Effects. Revised October 1988.

ANSI/NSF 61 - 1990. Drinking Water System Components - Health Effects. Revised May 1990.

National Water Well Association. State Authorities for Abating, Containing, and Monitoring Groundwater Pollution. December 1984.

Proceedings of the FOCUS Conference on Southwestern Groundwater Issues. March 23-25, 1988.

Nielsen, David M. and Aller, Linda. Methods for Determining the Mechanical Integrity of Class II Injection Wells. A cooperative study by the National Water Well Association, East Central University, and the Robert S. Kerr Environmental Research Laboratory, U. S. Environmental Protection Agency. National Water Well Association. 1984.

Roscoe Moss Company. A Guide to Water Well Casing and Screen Selection. 1982.

San Francisco Bay Regional Water Quality Control Board; Sanitary Engineering Environmental Health Research Laboratory, University of California, Berkeley; and Santa Clara Valley Water District. Assessment of Contamination from Leaks of Hazardous Materials in the Santa Clara Groundwater Basin, 205j Report. UCB/SEEHRL Report No. 85-6. July 1985.

Santa Clara Valley Water District. Groundwater Monitoring Guidelines. December 1983.

Southern California Cathodic Protection Committee. Tentative Deep Anode Standards to Comply With California Department of Water Resources Water Well Standards. Drawing Numbers A-497-S-1 and A-497-S-2. Revision of December 10, 1969.

Uni-Bell Plastic Pipe Association. Vinyl Chloride: The Control of Residual Vinyl Chloride Monomer in PVC Water Pipe. 1981

U.S. Environmental Protection Agency, Office of Drinking Water. Workshops on (Risk) Assessment and Management of Drinking Water Contamination. Revised March 1987.

Office of Groundwater Protection. Wellhead Protection, A Decision- Makers Guide. May 1987.

Guidelines for Delineation of Wellhead Protection Areas. June 1987.

Guidance for Applicants for State Wellhead Protection Program Assistance Funds Under the Safe Drinking Water Act. June 1987.

Office of Research and Development. Monitoring Groundwater Quality: Monitoring Methodology. EPA 600/4-76-026. June 1976.

Office of Solid Waste. Problem Areas in Groundwater Monitoring System Design for Waste Management Facilities. Notes from a Seminar Presented December 4-5, 1986.

Office of Waste Programs Enforcement and Office of Solid Waste and Emergency Response. RCRA Groundwater Monitoring Compliance Order Guidance (Final) and RCRA Groundwater

Monitoring Enforcement Guidance Document (Draft). August 1985.

Office of Waste Programs Enforcement and Office of Solid Waste and Emergency Response. RCRA Groundwater Monitoring Technical Enforcement Guidance Document. September 1986.

Office of Waste Programs Enforcement. RCRA Groundwater Monitoring Enforcement, Use of the TEGD and COG. Notes from a course sponsored by EPA Region IX and the RCRA

Enforcement Division, Office of Waste Programs Enforcement, March 3-5, 1987.

Office of Water Supply. DRASTIC: A Standardized System for Evaluating Groundwater Pollution Potential Using Hydrogeologic Settings. EPA 600/2-85-18. May 1985.

Office of Water and Waste Management. Procedures Manual for Groundwater Monitoring at Solid Waste Disposal Facilities. Publication SW- 611. Second printing, December 1980.

U.S. General Services Administration, National Archives and Records Service, Office of the Federal Register. Code of Federal Regulations, Title 49, Transportation, Chapter 1, Hazardous Materials Regulations Board, Department of Transportation, Part 192, Transportation of Natural and Other Gas by Pipeline: Minimum Federal Safety Standards. Subpart I -- Requirements for Corrosion Control. Edition of October 1, 1987.

U.S. Geological Survey. Basic Groundwater Hydrology. Water Supply Paper 2220. 1983.

Study and Interpretation of the Chemical Characteristics of Natural Water. Third Edition. Water Supply Paper 2254. 1985.

Water Systems Council. Water Systems Handbook. Eighth Edition. 1983.

Large Submersible Water Pump Manual. First Edition. 1986.

Recommended Standards (PAS-1) and Installation Procedures for Sanitary Water Well Pitless Adapters and Units. Sixth Edition, March 1987.

Williams, Dennis E. The Well/Aquifer Model, Initial Test Results. Roscoe Moss Company. 1981.

Periodicals

Civil Engineering. American Society of Civil Engineers. Published monthly since 1930.

Engineering News-Record. McGraw-Hill Publishing Company. Published weekly since 1902.

Groundwater. Journal of the Association of Groundwater Scientists and Engineers, a Division of the National Water Well Association. Published bimonthly since 1962.

Groundwater Age. National Trade Publications, Inc. Published monthly since 1966.

Groundwater Monitoring Review. Water well Journal Publishing Company in cooperation with the National Water Well Association. Published quarterly since 1981.

Groundwater Newsletter. Water Information Center, Inc. Published semi- monthly since 1971.

Journal of the American Water Works Association. Published bimonthly since 1920, quarterly between 1914 and 1919.

Materials Performance. National Association of Corrosion Engineers. Published monthly since January 1974. From March 1970 through December 1973 published as Materials Protection and

Performance. From 1962 through February 1970 published as Materials Protection.

Water Well Journal. Water Well Journal Publishing Company in cooperation with the National Water Well Association. Published monthly since 1948.

Western Water. Water Education Foundation. Published monthly since 1949.

Laws, Rules and Regulations

A. Pertinent laws and regulations of the State of California as contained in:

- California Code of Regulations

- California Business and Professions Code

- California Health and Safety Code

- California Public Resources Code

- California Water Code

B. The State Water Resources Control Board Model Water Well Ordinance.

C. Existing ordinances of the counties of California pertaining to the construction, alteration, and destruction of wells.

D. Laws, regulations, and recommendations of the various states pertaining to the construction, alteration, or destruction of wells.

APPENDIX D - SUGGESTED PROCEDURES FOR DISINFECTED WELLS

Disinfection of all wells is recommended to eliminate pathogenic organisms as well as organisms that can grow in wells and thereby cause clogging and effect the quality of water produced. Disinfection of the well is the final act of well construction or repair before it is placed in service. Wells should also be disinfected following repair or replacement of the pump and/or well maintenance. The procedures described in this appendix are recommended for disinfecting wells; however, other methods may be used provided it can be demonstrated that they will yield comparable results. For new wells, disinfection should take place following development (this will assure that the well is purged of drilling mud, dirt, and other debris that reduces the effectiveness of the disinfection), testing for yield, and installation of the pump. When there is a delay in pump installation, interim or partial disinfection should be undertaken.

Disinfection involves seven steps:

-

1. A chlorine solution containing at least 50 mg/l (or parts per million) available chlorine, is added to the well. Table 6 lists quantities of various chloride compounds required to dose 100 feet of water-filled casing at 50 mg/l for diameters ranging from 2 to 24 inches. For wells that have been repaired or when a pump has been repaired or replaced and, bringing the well back into service quickly is desired, the solution should contain at least 100 mg/l available chlorine. To obtain this concentration, double the amounts shown in Table 6.

-

2. The pump column or drop pipe shall be washed with the chlorine solution as it is lowered into the well.

-

3. After it has been placed into position, the pump shall be turned on and off several times (i.e., “surged”) so as to thoroughly mix the disinfectant with the water in the well. Pump until the water discharged has the odor of chlorine. Repeat this procedure several times at one-hour intervals.

-

4. The well shall be allowed to stand without pumping for 24 hours.

-

5. The water shall then be pumped to waste until the presence of chlorine is no longer detectable. The absence of chlorine is best determined by testing for available chlorine residual using a test kit designed for this purpose. Testing for available chlorine residual is simple and inexpensive. Test kits can be obtained from chemical supply houses, swimming pool suppliers, etc.

Disposal of the waste should be away from trees, shrubs, or lawns and into storm sewers, drainage ditches, etc. Note that heavily chlorinated water should not be wasted into the plumbing system of homes that utilize individual sewage disposal systems (septic tanks). Such strong disinfectants could neutralize the bacteria needed to stabilize the sewage and also could damage the soil adsorption system.

-

6. A bacteriological sample shall be taken and submitted to a laboratory for examination (see Appendix D).

-

7. If the laboratory analysis shows the water is not free of bacterial contamination, the disinfection procedure should be repeated. Depending on the level of contamination, it may be necessary to use a higher concentration chlorine solution (several times that shown in Table 6). The water should then be retested. If repeated attempts to disinfect the well are unsuccessful, a detailed investigation to determine the cause of the contamination should be undertaken.

Where small individual domestic wells to be treated are of unknown depth or volume, at least one pound (0.45 kilograms) of calcium hypochlorite (70 percent available chlorine) or two gallons (7.5 liters) of household bleach (sodium hypochlorite), such as Clorox or Purex, may be used in lieu of the chemicals shown in Table 6.

Table 6 Chlorine Compound Requires to Dose 100 Feet of Water-Filled Casing at 50 Milligrams Per Liter1

| Chlorine Compounds | |||

|---|---|---|---|

| Diameter of Casing (Inches) | (70%) Calcium Hypochlorite2 (Dry Weight) 3 | (25%) Chloride of Lime (Dry Weight)3 | (5.25%) Sodium Hypochlorite4 (Liquid Measure) |

|

2 |

1/4 oz (7 g) |

1/2 oz (14 g) |

2 oz (59 mL) |

|

4 |

1 oz (28 g) |

2 oz (57 g) |

9 oz (266 mL) |

|

6 |

2 oz (57 g) |

4 oz (113 g) |

20 oz (0.6 L) |

|

8 |

3 oz (85 g) |

7 oz (0.2 kg) |

2-1/8 pts (1.0 L) |

|

10 |

4 oz (113 g) |

11 oz (0.3 kg) |

3-1/2 pts (1.7 L) |

|

12 |

6 oz (0.2 kg) |

1 lb (0.45 kg) |

5 pts (2.4 L) |

|

16 |

10 oz (0.3 kg) |

2 lb (0.9 kg) |

1 gal (3.8 L) |

|

20 |

1 lb (0.45 kg) |

3 lb (1.4 kg) |

1-2/3 gal (6.3 L) |

|

24 |

1-1/2 lb (0.7 kg) |

4 lb (1.8 kg) |

2-1/3 gal (8.8 L) |

Notes for Table 6:

1. Some authorities recommend a minimum concentration of 100 mg/L. To obtain this concentration, double the amounts shown.

2. HTH, Perchloron, Pittchlor, etc.

3. Where dry chlorine is used, it should be mixed with water to form a chlorine solution prior to placing it into the well. Note that dry chlorine shouldalwaysbe added to water, not vice versa. Further, the chemical should be added slowly. These precautions are necessary to lessen the possibility of a violent chemical reaction.

4. Household bleaches such as Chlorox, Purex, etc.

APPENDIX E - COLLECTION OF WATER QUALITY SAMPLES

Water from all new wells should be sampled in order to determine the quality of the water that is being produced. The type of analysis that will be made is dependent on the expected use of the water. For example, individual domestic wells should be sampled for determination of bacterial quality and chemical quality. The water from agricultural wells is generally examined only for the presence of specific chemicals unless there is the likelihood that there will be incidental domestic use of the water, in which case the bacterial quality ought to be determined too.

Recommendations regarding the types of analyses to be performed for the various uses of water will be found in numerous references on water quality and groundwater; however, it is best to consult with local agencies such as county farm advisors, health departments or water service agencies (irrigation or water districts). Sampling of community water supply wells is covered by requirements of the California Department of Health Services. Refer to Section 4026, California Health and Safety Code and Chapter 15, "Domestic Water Quality and Monitoring" of Title 22, California Administrative Code.

Bacterial Sampling

For individual domestic wells, technical advice regarding the collection of bacteriological samples may be obtained from the local health departments or from the laboratories that will examine the sample. If no technical assistance is available, the following procedure will suffice: A sterile sample bottle, preferably one provided by the laboratory, must be used. It is extremely important that nothing except the water to be analyzed come in contact with the inside of the bottle or the cap; the water must not be allowed to flow over an object or over the hands and into the bottle while it is being filled. If the water is collected from a sample tap, turn on the tap and allow the water to flow for 2 or 3 minutes before collecting the sample. An alternative is to sterilize the tap first with a propane torch or similar device. Do not rinse the sample bottle. The sample should be delivered to the laboratory as soon as possible and in no case more than 30 hours after its collection. During delivery, the sample should be kept as cool as possible (but not frozen).

Chemical Sampling

Generally, a routine mineral analyses (determination of the concentrations of the common minerals such as calcium, sodium, chloride, sulfate, etc.) plus analyses for selected minor elements will suffice, particularly where there is no prior knowledge of the chemical quality of the water in the area where the well is located. Where quality conditions in the surrounding area are known, a more selective analysis may be made. For specified uses it may also be desirable to make analysis for concentrations of certain constituents (such as iron and manganese in the case of domestic water or boron in irrigation water). Organic chemicals are not routinely determined. Information or advice on chemical quality conditions may be obtained from local agencies such as the county farm advisors, health departments, etc.

The sample should be collected after the well has been pumped long enough to remove standing water and development and disinfectant chemicals, and to ensure that water from the producing formation(s) has entered the well. The water sample should be collected in a chemically clean container, preferably one obtained from the laboratory that will perform the analysis. The container should be rinsed several times with the water to be sampled prior to collecting the sample. The laboratory performing the analysis should issue instructions regarding the quantity of sample required and whether or not preservatives are needed. However, one-half gallon (1.9 liters) is usually sufficient for a routine mineral analysis; one gallon (3.8 liters) when analyses for minor elements (i.e., iron, manganese, etc.) is also required. Sample quantities for organic chemicals vary according to the type of analysis, and range from very small amounts up to several gallons (liters). In addition, where organic chemicals are to be determined, special sampling procedures and equipment may be required. This is particularly true for volatile organic compounds.

In all cases the temperature of the water should be determined immediately upon collection of the sample.

APPENDIX F - BIBLIOGRAPHY

- Ahrens, Thomas P. “Well Design Criteria. Part 2”. Water Well Journal. November 1957.

- Ahrens, Thomas P. “Corrosion in Water Wells“. Water Well Journal. March and April 1966.

- Ahrens, Thomas P. “Basic Considerations of Well Design“. Water Well Journal. April, May, June and August 1970. (Four parts)

- American Association for Vocational Instructional Materials. “Planning for an Individual Water System“. 1973.

- American Society of Agricultural Engineers. “Designing and Constructing Water Wells for Irrigation“. Tentative Recommendation: ASAE R 283 (T). December 1964.

- American Water Works Association. “Standard Specifications for Deep Wells“. AWWA A-100-66. 1967.

- American Water Works Association. “Groundwater“. AWWA Manual No. M21. 1973.

- American Water Works Association. “Standard for Vertical Turbine Pumps - Line Shaft and Submersible Types“. AWWA E-101-77. June 1977.

- American Water Works Association. “PVC Pipe - Design and Installation”. AWWA Manual No. M23. 1980.

- Anderson, K. “Water Well Handbook”. Missouri Water Well Drillers Association. 1963.

- Associated Drilling Contractors of the State of California. “Recommended Standards for Preparation of Water Well Construction Specifications”. September 17, 1960.

- Brantly, J. E. “Rotary Drilling Handbook”. Palmer Publications. Fifth Edition. 1952.

- California Department of Public Health, Bureau of Sanitary Engineering. “Occurrence of Nitrate in Groundwater Supplies in Southern California”. February 1963.

- California Department of Public Works, Division of Water Resources. “Groundwater Basins in California“. Water Quality Investigations Report No. 3. November 1952.

- California Department of Public Works, Division of Water Resources. “Abstract of Laws and recommendations Concerning Water Well Construction and Sealing in the United States“. Water Quality Investigations Report No. 9. April 1955.

- California Department of Transportation. “Standard Specifications“. January 1981.

- California Department of Water Resources. “Water Quality and Water Quality Problems, Ventura County“. Bulletin 75. February 1959.

- California Department of Water Resources. “Intrusion of Salt Water Into Groundwater Basins of Southern Alameda County“. Bulletin 81. December 1960.

- California Department of Water Resources. “Investigation of Nitrates in Groundwater, Grover City, San Luis Obispo County”. April 1962.

- California Department of Water Resources. “Water Well Standards: State of California“. Bulletin No. 74. February 1968.

- California Department of Water Resources. “Cathodic Protection Well Standards: State of California“. Bulletin No. 74-1. March 1973.

- California Department of Water Resources. “California’s Groundwater“. Bulletin No. 118. September 1975.

- California Department of Water Resources. “Sea-Water Intrusion in California“. Inventory of Coastal Groundwater Basins. Bulletin No. 63-5. October 1975.

- California Department of Water Resources. “Guide to the Preparation of the Water Well Drillers Report“. October 1977.

- California Department of Water Resources. “WATER WELLS and What You Should Know About Them“. October 1977.

- California Department of Water Resources. “The 1976-1977 California Drought - A Review“. May 1978.

- California Department of Water Resources. “Groundwater Basins in California”. A Report to the Legislature in Response to Water Code Section 12924. Bulletin 118-80. January 1980.

- California Department of Water Resources. San Joaquin District. “Investigation of Groundwater Contamination by Dibromochloropropane in the Dinuba Area”. Memorandum Report. August 1980.

- California Legislature, Assembly Interim Committee on Water. “State and Local Responsibilities for Water Resources”. Assembly Interim Committee Reports 1965-67. Volume 26, No. 17. December 1966.

- California State Water Pollution Control Board. “Final report on Field Investigation and Research on Wastewater Reclamation and Utilization in Relation to Underground Water Pollution”. Publication No. 6. 1953.

- California State Water pollution Control Board. “Report on the Investigation of Travel of Pollution”. Publication No. 11. 1954.

- California State Water Pollution Control Board. “Effect of Refuse Dumps on Groundwater Quality”. Publication No. 24. 1961.

- California State Water Quality Control Board. “Water Quality Criteria”. By McKee, J. and Wolf, H. W. Second Edition. Publication No. 3-A 1963.

- Campbell, Michael D. and Lehr, Jay H. “Water Well Technology”. McGraw- Hill Book Company, Inc. 1973.

- Clark, N. L. and LuChang, S. “Enteric Viruses in Water”. American Water Works Association Journal. Volume 51. October 1959.

- Crocker, S. ”Piping Handbook”. Fourth Edition. McGraw-Hill Book Company, Inc. 1945.

- Davis, Stanley N. and DeWiest, Roger J. M. “Hydrogeology”. John Wiley and Sons, Inc. 1966.

- Driscoll, Fletcher G., Hanson, David T. and Page, Lyn. “Well-Efficiency Project Yields Energy-Saving Data”. The Johnson Drillers Journal, March- April, May-June, and September-October, 1980, and First Quarter, 1981. (Four parts)

- Gordon, R. W. “Water Well Drilling with Cable Tools”. Bucyrus-Erie Company. 1958.

- Ham, Herbert H. “Water Wells and Groundwater Contamination”. Bulletin of the Association of Engineering Geologists. Volume VIII, No. 1. 1971.

- Helweg, Otto J., Scalmanini, Joseph C. and Scott, Verne H. “Energy and Efficiency in Wells and Pumps”. Presented to the Twelfth Biennial Conference on Groundwater sponsored by the University of California, Water Resources Center and the California Department of Water Resources, at Sacramento, California, September 20-21, 1979. California Water Resources Center, University of California, Davis. Report No. 45. November 1979.

- Idaho Department of Water Resources. “Minimum Well Construction Standards”. Rules and regulations. June 1975.

- International Association of Plumbing and Mechanical Officials. “Uniform Plumbing Code”. 1976 Edition. 1976.

- Johnson Division, Universal Oil Products Company, Inc. “Groundwater and Wells”. 1966.

- Kurt, Carl E. and Warman, James C. “Engineering Performance of Thermoplastic Water Well Casings”. WRRI Bulletin 44. Water Resources Research Institute, Auburn University. July 1980.

- Lenain, A. F. “The Impact of Nitrates on Water Use”. Presented to the California Section Meeting, American Water Works Association, Los Angeles, California. October 27, 1966.

- Library of Congress, Congressional Research Service. “Resource Losses from Surface Water, Groundwater, and Atmospheric Contamination: A Catalog”. A report prepared for the Committee on Environment and Public Works, U. S. Senate, 96th Congress, Serial No. 96-9. March 1980.

- Lieber, M., et al. “Cadmium and Hexavalent Chromium in Nassau County Groundwater“. Journal of the American Water Works Association. Volume 56. June 1964.

- Luhdorff, Jr., Eugene E. “Protecting Groundwater Quality - Some Problems and Solutions“. Presented at the Ninth Biennial Conference on Groundwater sponsored by the University of California, Water Resources Center and the California Department of Water Resources at Goleta, California, September 13-14, 1973. Water Resources Center, University of California, Davis. Report No. 26. December 1973.

- Minnesota Board of Health. “The Water Well Construction Code and Amendments to Regulations Relating to the Licensing of Water Well Contractors“. Adopted April 11, 1974.

- Moore, Preston L. “Drilling Practices Manual“. The Petroleum Publishing Company. 1974.

- Moss, Jr., R. “Evaluation of Materials for Water Well Casings and Screens“. Paper presented before the National Association of Corrosion Engineers, Western Region Meeting, San Francisco, California. October 1, 1966.

- National Sanitation Foundation. “Standard No. 14 for Plastic Piping System Components and Related Materials“. As revised November 1978.

- National Water Well Association. “Water Well Drillers Beginning Training Manual“. 1971.

- National Water Well Association and The Plastic Pipe Institute “Manual on the Selection and Installation of Thermoplastic Water Well Casing“. October 1, 1980.

- Oregon Drilling Association, Incorporated. “Manual of Water Well Construction Practices for the State of Oregon“. Second Edition. 1968.

- Oregon Water Resources Department. “Rules and Regulations Prescribing General Standards for the Construction and Maintenance of Water Wells in Oregon“. Effective January 1, 1979. Published jointly with Oregon Department of Human Resources, Health Division and Oregon Department of Commerce, Building Codes Division.

- Rossum, John R. “Control of Sand in Water Systems“. Journal American Water Works Association. Volume 46, No. 2. February 1954.

- Schrock, B. J. “Thermosetting Resin Pipe“. Presented at the American Society of Civil Engineers Fall Convention, San Francisco, California. October 17-21, 1977. Preprint No. 3088.

- Schwalen, H. C. “The Stovepipe or California Method of Well Drilling as Practised in Arizona“. University of Arizona, College of Agriculture. Bulletin No. 112. November 1, 1925.

- Speedstar Division, Koehring Company. “Well Drilling Manual“. (Updated)

- Spiridonoff, S. V. “Design and Use of Radial Collector Wells“, Journal American Water Works Association. Volume 56. June 1964.

- State of Nevada, Department of Conservation and Natural Resources, Division of Water Resources. “Rules and Regulations for Drilling Wells and Other Related Material“. Undated.

- Stead, F. M. “A Discussion of Factors Limiting the Bacterial Pollution of Underground Waters by Sewage“. Report on the California State Assembly Interim Fact-Finding Committee on Water Pollution. 1949.

- Todd, D. K. “Groundwater Hydrology“. John Wiley and Sons, Inc. 1959.

- Tolman, C. F. “Groundwater“. McGraw-Hill Book Company, Inc. 1939.

- U. S. Bureau of Reclamation. “Groundwater Manual“. First Edition. 1977.

- U. S. Department of Commerce, Environmental Science Services Administration. “CLIMATES OF THE STATES - Climate of California“. Climatography of the United States No. 60-4. Revised June 1970.

- U. S. Department of Housing and Urban Development. “Minimum Property Standards for One and Two Family Dwellings“. 1973 Edition with Revisions for 1974, 1975 and 1976.

- U. S. Departments of the Army and the Air Force. “Wells“. Technical Manual TM5-297 and Air Force Manual 85-23. August 1, 1957.

- U. S. Environmental Protection Agency, Office of Air and Water Programs. “Groundwater Pollution from Subsurface Excavations“. 1973. EPA 430/9-73- 012.

- U. S. Environmental Protection Agency, Office of Research and Development. “Subsurface Biological Activity in Relation to Groundwater Pollution“. September 1973. EPA 660/2-73-014.

- U. S. Environmental Protection Agency, Office of Water Programs, Water Supply Division. “Manual of Individual Water Supply Systems“. Revised 1974. EPA 430/9-74-007.

- U. S. Environmental Protection Agency, Office of Water Supply. “Manual of Water Well Construction Practices“. 1976. EPA 570/9-75-001.

- U. S. Environmental Protection Agency, Office of Water Supply. “National Interim Primary Drinking Water Regulations“. 1976. EPA 570/9-76- 003.

- U. S. Environmental Protection Agency, Office of Research and Development. “Impact of Abandoned Wells on Groundwater“. August 1977. EPA 600/3-77-095.

- U. S. Geological Survey. “Study and Interpretation of the Chemical Characteristics of Natural Water“. Water Supply Paper 1473. 1959.

- U. S. Geological Survey. “A Primer on Groundwater“. 1963.

- U. S. Geological Survey. “Reverse Circulation Drilling, an Improved Tool for Production Wells and Exploratory Holes“. Open File Report. May 1963.

- U. S. Geological Survey. “A Primer on Water Quality“. 1965.

- U. S. Geological Survey. “Regional Trends in Water Well Drilling in the United States“. Circular 533. 1966.

- U. S. Geological Survey. “Evaluation and Control of Corrosion and Encrustation in Tube Wells of the Indus Plains, West Pakistan“. Water Supply Paper 1608-L. 1969.

- U. S. Public Health Service. “Groundwater Contamination“. Proceedings of the 1061 Symposium. Technical Report W61-5. 1961.

- U. S. Public Health Service. “Recommended State Legislation and Regulations - Urban Water Supply and Sewerage Systems Act and Regulations - Water Well Construction and Pump Installation Act and Regulations - Individual Sewerage Disposal Systems Act and Regulations. July 1965.

- United States Senate, Eighty-ninth Congress, Committee on Interior and Insular Affairs. “Mineral and Water Resources of California - Part II, Water Resources; Section I; Water Resources Appraisal“. Report of the U. S. Department of the Interior, Geological Survey, in collaboration with the California Department of Water Resources. 1966.

- University of California. “Irrigation Wells and Well Drilling“. Agricultural Experiment Station, College of Agriculture. Circular 404. May 1951.

- University of California. “Proceedings - Symposium on Agricultural Waste Waters, Davis, California, April 6-8, 1966“. Water Resources Center Report No. 10.

- University of California. “Water Wells and Pumps: Their Design, Construction, Operation and Maintenance“. Division of Agricultural Sciences. Bulletin 1889. May 1978.

- Vertical Turbine Pump Association. “Turbine Pump Facts“. 1962.

- Walker, T. R. “Groundwater Contamination in the Rocky Mountain Arsenal Area, Denver, Colorado“. The Geological Society of America. Bulletin 72, Volume 3. March 1961.

- Washington Department of Ecology. “Minimum Standards for Construction and Maintenance of Water Wells“. Chapter 173-160 Washington Administrative Code. January 10, 1979.

- Water Systems Council. “Water Systems Handbook“. Sixth Edition. 1977.

- Water Systems Council. “What you need to know about WELLS & WATER SYSTEMS“. 1975.

- Water Well Journal. “Water Well Drilling Methods“. Reprint of seven papers presented at the 1957 National Water Well Exposition.

- Weibel, S. R., et al. “Waterborne-Disease Outbreaks, 1946-60“. Journal of the American Water Works Association. Volume 56. August 1964.

Quick Links

- Bulletin 74-81 Introduction

- Bulletin 74-90 Introduction

- Part I. General, Water Well Standards

- Part II. Water Well Construction

- Part III. Destruction of Water Wells

- Monitoring Well Standards, Introduction

- Part I. Monitoring Well Standards, General

- Part II. Monitoring Well Construction

- Part III. Destruction of Monitoring Wells

- Cathodic Protection Well Standards

- Part I. General, Cathodic Protection Well Standards

- Part II. Cathodic Protection Well Construction

- Part III. Destruction of Cathodic Protection Wells

- Appendices